Cov Lus Qhia Txog Kev daws teeb meem

Ua kom cov ntawv xov xwm floater ntau dua, DESOATEN ACS

Cov Lus Qhia Txog Kev Txiav Txim Siab Zoo Tshaj Plaws

Yog tias koj tsav tsheb hauv Xinjiang, ua raws Lianhuo Expressway rov qab mus rau Urumqi, tom qab hla Guozigou Choj, koj yuav dhau los ntawm lub qhov av ntev, thiab lub sijhawm koj tawm hauv lub qhov av - lub xiav loj ntshiab yuav ntws rau hauv koj lub qhov muag.

Vim li cas peb thiaj nyiam cov pas dej? Tej zaum vim tias qhov chaw ci ntsa iab ntawm lub pas dej ua rau peb muaj kev thaj yeeb nyab xeeb, tsis yog khov kho zoo li dej qhov dej lossis qias neeg zoo li dej tsaws tsag, tab sis tswj hwm thiab muaj sia nyob, raws li kev zoo nkauj sab hnub tuaj ntawm kev ua kom lub siab tus thiab kev xav txog tus kheej.

Floater yog tej zaum cov qauv tawv uas qhia tau qhov zoo nkauj no zoo tshaj plaws.

Cov tawv nqaij uas muaj cov khoom siv floater yog ib hom tawv uas siv ntau vim nws muaj cov noob tshwj xeeb, ua rau nws zoo nkauj thiab xis nyob. Nws siv dav hauv cov khau yooj yim, cov khau sab nraum zoov thiab cov rooj tog zaum. Nws kuj siv los txhim kho cov qauv thiab ua kom cov tawv zoo nkauj dua, vim tias qhov tawg zais qhov puas tsuaj rau tawv.

Tiam sis ib daim tawv zoo uas ntab dej kuj xav tau cov tawv rawhide qub heev. Nws xav tau kom daim tawv wetblue ntub sib npaug zoo, txwv tsis pub nws yuav ua rau muaj teeb meem tawg tsis sib npaug. Txawm li cas los xij, txawm tias daim tawv wetblue tau kho zoo los xij, qhov sib txawv ntawm cov tawv nqaij qub ntawm cov tsiaj, tshwj xeeb tshaj yog qhov sib txawv loj ntawm cov pob txha nraub qaum thiab sab plab, tuaj yeem ua rau tawg qhov teeb meem loj tshaj plaws ntawm cov tawv floater. Yog li ntawd, los teb rau qhov teeb meem no, pab pawg neeg txiav txim siab tau qhia txog kev daws teeb meem tshiab.

DESOATEN ACS

Cov polymers ua npuas ncauj

Cov tshuaj polymer tanning zoo tshaj plaws rau cov qauv float

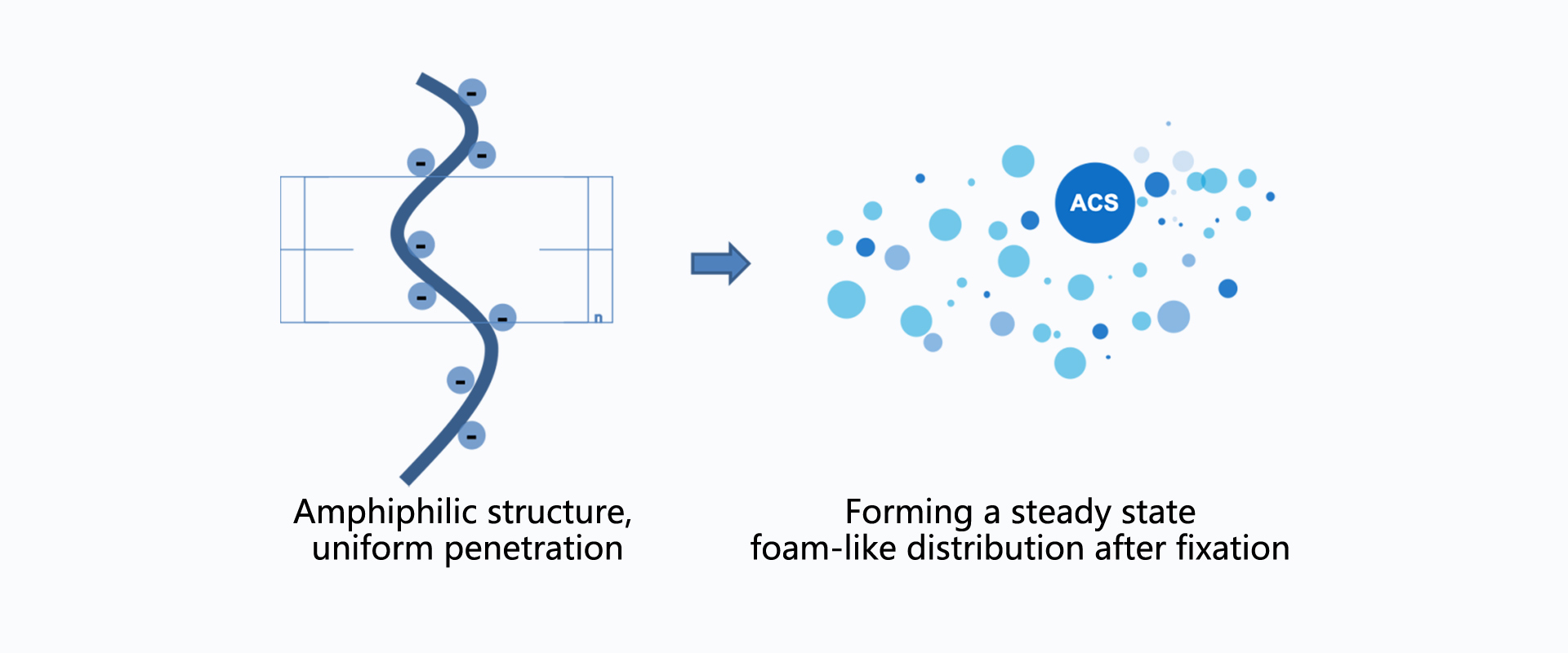

Los ntawm kev kho cov qauv ntawm cov khoom thiab tswj qhov loj me ntawm cov molecular, DESOATEN ACS tau faib ua homogeneously hauv daim tawv nqaij yam tsis tau khi nruj rau cov fibers thiab chromium complexes, thiab tau faib ua cov qauv zoo li ua npuas ncauj thoob plaws hauv daim tawv nqaij, yog li muab cov homogeneous, kis mus rau lwm qhov thiab tsis txhob ntsws cov noob ntoo.

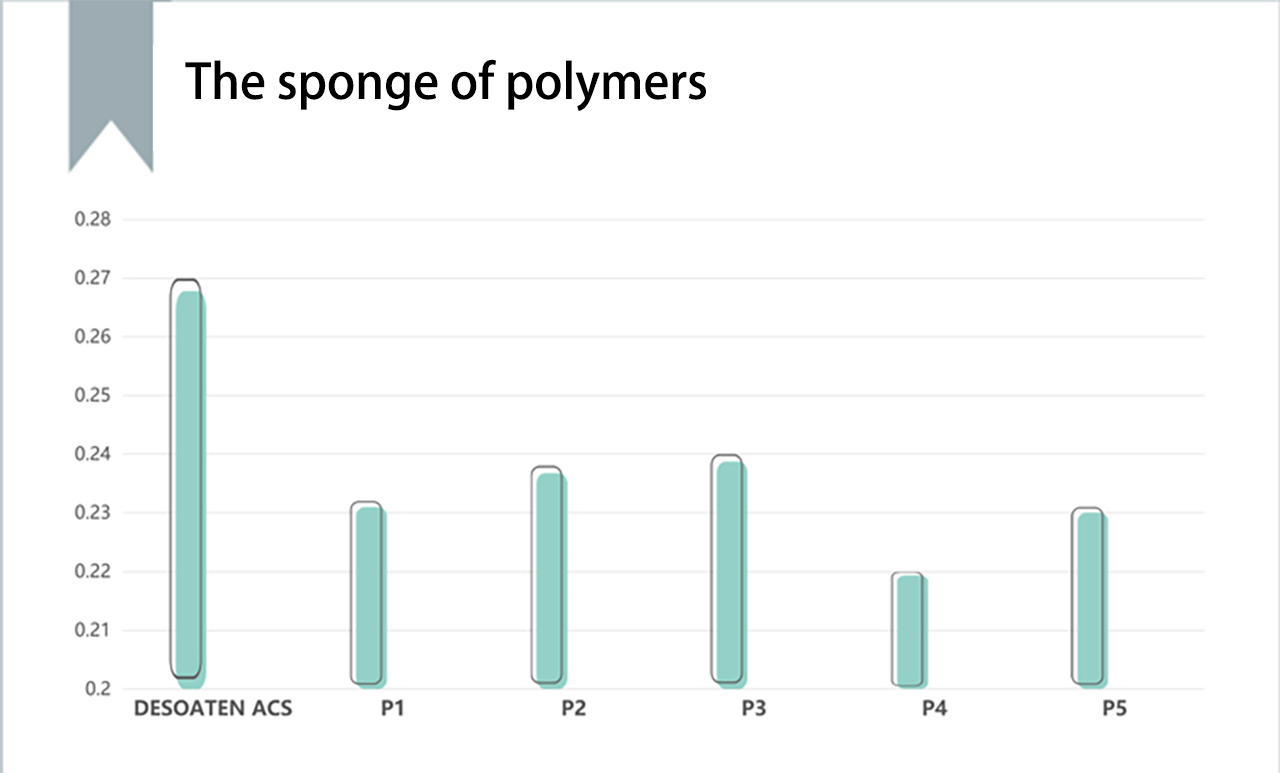

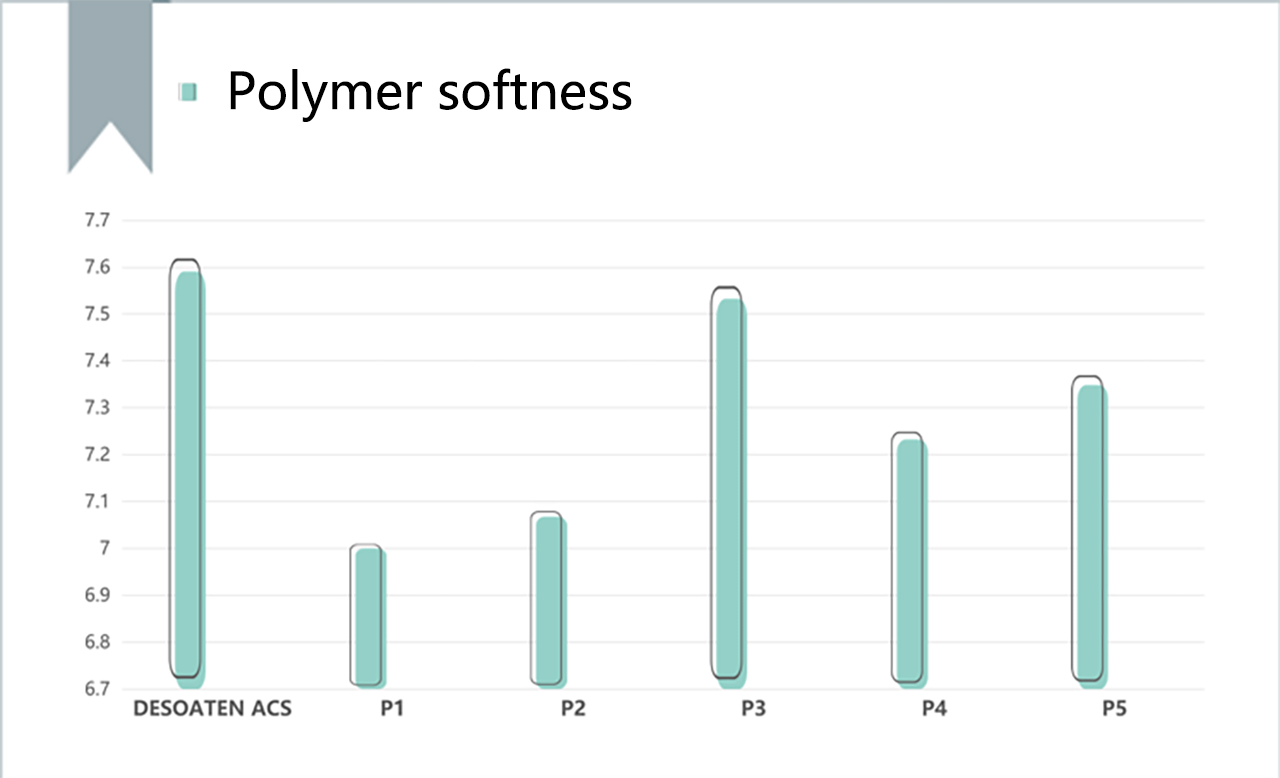

Tom qab ziab thiab milling cov txheej txheem, qhov tawg tau sib npaug zos rau sab nraub qaum thiab tsis loj dhau ntawm sab thiab lub plab, yog li ua tiav qhov loj me sib xws thiab tus kov mos mos yam tsis tuab. (Cov ntaub ntawv sim yog raws li nram no)

Txawm hais tias nws yog qhov teeb meem ntawm kev rhuav tshem qhov kev sib kis zoo ntawm cov neeg sawv cev tanning, peb, cov kws ua haujlwm tanning thiab cov neeg ntawm DECISION, yuav ua haujlwm rau txhua nti ntawm cov txheej txheem tanning los tsim kev sib txuas rau lub neej zoo nkauj dua.

Vim li cas thiaj pom zoo:

Txhim kho cov qoob loo ntawm tawv nqaij

Txawm tawg

cov qauv amphiphilic, kev nkag mus sib npaug

Qhov loj me ntawm qhov tawg tag nrho yog sib xws thiab tus kov yog mos yam tsis muaj thickening

Daim tawv nqaij nthuav dav thiab qhov saum npoo ntawm cov noob tsis ua rau tawv dhau.

Kev txhim kho kom ruaj khov tau dhau los ua ib feem tseem ceeb heev hauv kev lag luam tawv, txoj kev mus rau kev txhim kho kom ruaj khov tseem ntev thiab muaj ntau yam kev cov nyom.

Ua ib lub tuam txhab uas muaj lub luag haujlwm, peb yuav ua qhov no ua peb lub luag haujlwm thiab ua haujlwm tas li thiab tsis muaj zog mus rau lub hom phiaj kawg.

Tshawb nrhiav ntxiv